Next time you pass by one of those large steel feed bins on some farm in the countryside, chances are if you squint your eyes you’ll catch a rubber mallet dangling from its side.

A farmer will grasp the mallet and knock on different heights of the steel feed bin, straining his or her ears like an orchestra conductor for the sound of hollow, which indicates its time to call the feed mill and schedule a delivery.

That’s a lot of guesswork when you consider there are tens-of-thousands of feed bins across Canada storing thirty million tonnes of animal feed –a complex blend that can include corn, wheat, barley, and minerals often in pellet form – produced every year for farmers raising chickens, pigs and cattle.

That’s a lot of guesswork when you consider there are tens-of-thousands of feed bins across Canada storing thirty million tonnes of animal feed –a complex blend that can include corn, wheat, barley, and minerals often in pellet form – produced every year for farmers raising chickens, pigs and cattle.

Farmers are incredibly busy people, so checking feed mills can sometimes fall to the bottom of a list of urgent priorities, and so feed mills often field calls from panicked farmers who are down to the last kernels of feed, requiring changes in the mill’s production schedules to meet the crisis.

In addition, in many cases, feed can travel over 400 kilometers by semi-truck from mill to farm, so oftentimes the transport arrives with feed for Farmer A, only to learn that Farmer B next door is low, requiring a separate and costly delivery.

Enter Randall Schwartzentruber, a thirty-six year-old graduate of Emanuel Bible College with a passion for youth ministry and – technology.

About three years ago while working for Slinger Solutions – an automation consulting company in Kitchener-Waterloo – he heard of a feed mill looking for a solution that would notify them when a farmer’s bin was less than a quarter full.

“There really was no good solution, is what they told me,” says Schwartzentruber. “I went home and spent three hours that night on Google looking up solutions.”

In his spare time, he experimented with various off-the-shelf sensors – fixed point proximity sensors, ultrasonic and lasers – before coming to the conclusion that if this problem was going to be solved, it was going to take someone building something new and innovative.

The first challenge was that any sensor or camera available was quickly defeated by the dust inside the feed bins.

The second challenge was that the feed often formed an irregular shape inside the bins – with peaks and valleys that sometimes provided false feed level readings.

One year into development he felt like he had something, so he went to a poultry convention and casually pulled feed mill representatives aside to talk about his solution.

“The reception was more favourable than I expected, and I realized the market is absolutely massive,” says Schwartzentruber. “I went to my boss and asked for some time off to focus on refining the technology.”

He never went back. A few months later he co-founded BinSentry, a start-up headquartered in picturesque New Hamburg, Ontario.

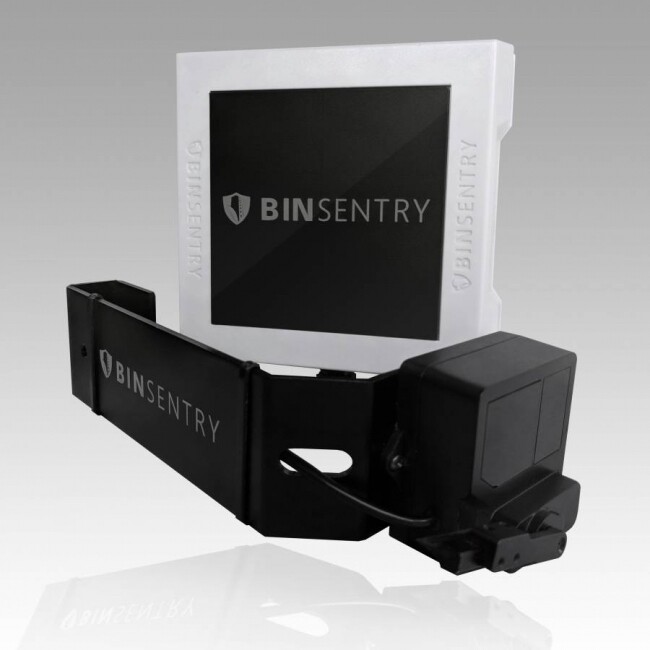

There are competitors currently on the market, he says, but what sets BinSentry apart is its proprietary self-cleaning LiDAR sensor that solves the dust challenge that leaves many technologies inoperable after a short period of time.

Farmers and operators love that it’s easily installed in fifteen minutes – about the time it takes to hang a mallet – and the combination of solar power and low battery usage means there is no maintenance required.

Most importantly, BinSentry uses artificial intelligence and predictive modelling to learn how the farms connected to each feed bin consumes the feed, and that critical information enables mills to be proactive by accurately forecasting when bins will be empty.

With a typical feed mill servicing between one and two thousand feed bins – BinSentry allows the operators to plan their production schedules far in advance and – just as important – coordinate their deliveries.

A larger feed-mill can clock upwards of five million kilometres per year transporting feed to farms, says Schwartzentruber, which equates to over $10 million per year in travel costs alone.

“If we can shave off five or ten percent of the cost of transport by making delivery more efficient, we’ve done our part,” he says.

“If we can shave off five or ten percent of the cost of transport by making delivery more efficient, we’ve done our part,” he says.

Word began to spread and Schwartzentruber began receiving emails and phone calls from mills and farmers across North America. Then the word got out on social media.

“Twitter is the preferred mode of communication for farmers,” he says. “It spreads like wildfire.”

On the cusp of some electric growth, it was an opportune time to connect with WEtech Alliance – a Regional Innovation Centre based in Windsor, Ontario that helps tech companies scale.

“I was impressed with the number of programs, resources and connections WEtech provided, especially in the early stages,” says Schwartzentruber.

In addition to providing business advisory services, and connections to engineering firms and hardware designers in Windsor and across Ontario, WEtech helped BinSentry take advantage of the MaRS Embedded Executive program, which provided $30,000 to hire on a sales director.

To date BinSentry has deployed numerous pilot projects with mills in both Canada and the US with over 1000 units slated for install in the near future as the company ramps-up their installation speed and adds installation crews.

At present BinSentry has a team of eight people and expects that number to grow over the coming months.

“We’re fielding interest from all over the world from both mills and major top-down integrators,” says Schwartzentruber. “We are currently in the midst of a major rollout for Wallenstein Feed, Canada’s largest independent feed mill, who is proudly providing our technology to a significant portion of their customer base.”

Although he is no longer a youth minister, and years removed from Emmanuel Bible College, Schwartzentruber remains involved in his church and connected to community, all the while following where his natural passion for technology leads him.

“That journey has really informed how we do business and especially how we treat our employees,” says Schwartzentruber. “Agriculture is one of those massively untapped markets where tech is concerned, but it remains a people business first.”

Dr. Irek Kusmierczyk, PhD is the Director of Partnerships at WEtech Alliance – a Regional Innovation Centre funded by the Government of Ontario that helps technology companies scale. BinSentry is a client.