Friday, July 7th – CEI & CS Wind

Centre for Engineering Innovation (CEI)

We started our day today by heading to the Centre for Engineering Innovation (CEI) at the University of Windsor, just across from the University of Windsor EPICentre. We first heard from Dr. Lindsay Miller, who gave us a short presentation on the advantages and struggles associated with renewable energy. For example, renewable energy is called intermittent, meaning that it is only available at certain times, like when the sun is shining or the wind is blowing. This can be difficult to link with our energy demand, since humans follow a steady cycle in which energy usage is highest midday and lowest during the night (which happens to be when the wind blows the most). Another problem is that renewable energy can require many resources, such as solar which requires huge amounts of water to keep clean and therefore operating at peak performance.

The CEI & Energy Storage

One of the crucial aspects that needs to be solved for renewable energy to be effective is energy storage. Conventional batteries often use far too many resources and can be inefficient. It was extremely interesting to hear that the University of Windsor has pioneered a new method of energy storage. Reserachers designed balloons that store air under high pressure underwater. The water keeps constant pressure on the air balloons, so that when the valves are opened the air comes rushing out and can therefore be used to regenerate the electricity. These are problems that will need effective solutions before renewable energy can completely replace our existing technologies, and it is clear that the University of Windsor intends to play a major role in this process.

CEI – Turbulence and Energy Lab

We then visited the Turbulence and Energy lab, where we met with Dr. David Ting and his graduate students. We learned about the research they conduct in the lab and all of the different ideas they are testing. They perform different tests and experiments that enable us to better design systems like wind turbines and energy storage. We viewed the huge wind tunnel they have there, which is used to test different designs and their aerodynamic efficiency. Some of the graduate students fired up the wind tunnel for us and demonstrated how they tested one of the aerofoils they made, with a camera positioned above the aerofoil to observe the interactions. It was super cool to see everything the Turbulence and Energy lab does and it was great to see some of the most interesting research being conducted at the University of Windsor CEI!

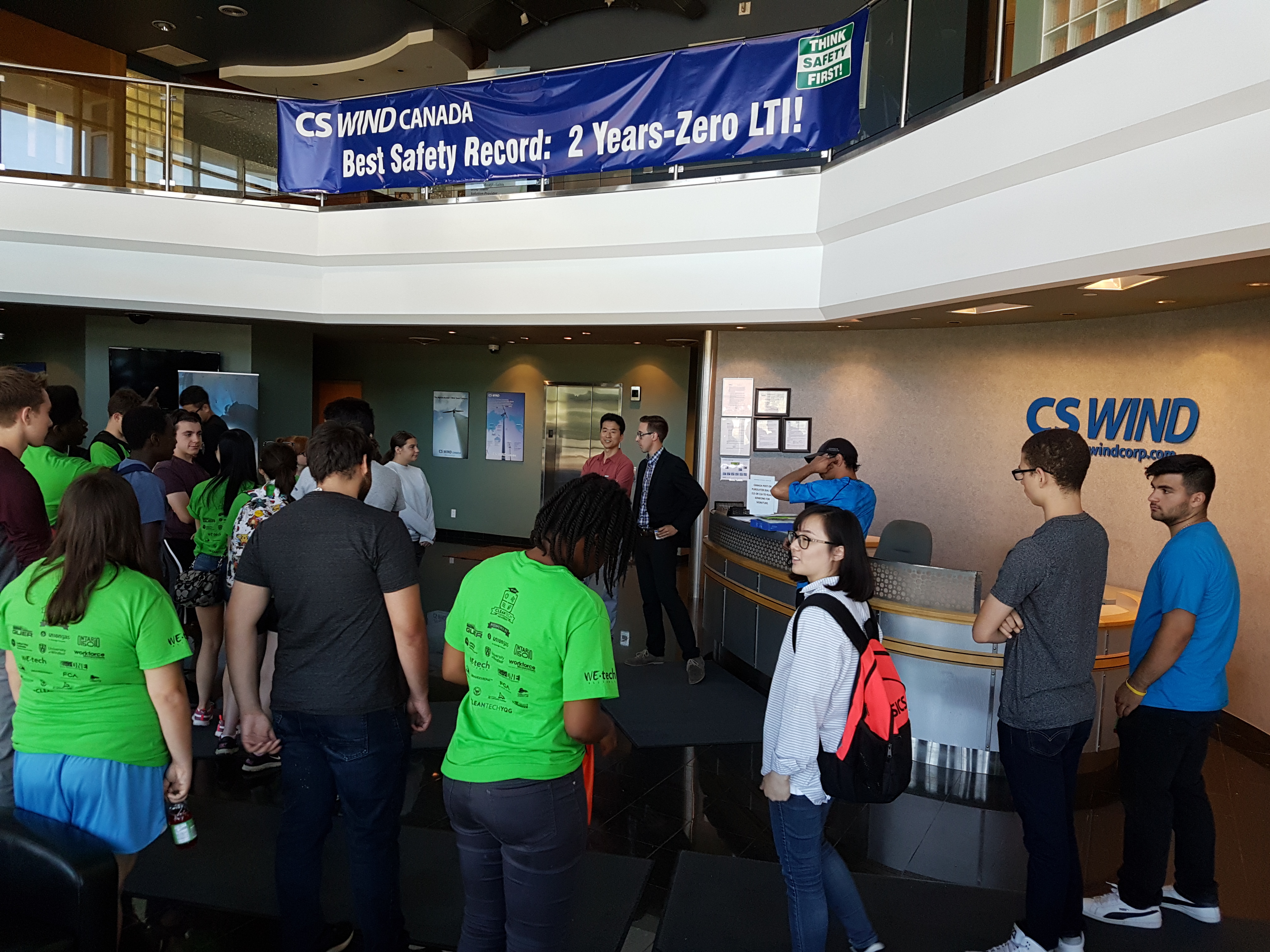

CS Wind

We then took a Transit Windsor bus on a short trip to CS Wind Canada’s manufacturing plant on the east side of the city, close to Tecumseh. We met with Paolo Piunno, one of CS Wind’s project manager. First, we heard more about CS Wind, a global company with five manufacturing sites across the world. The plant in Windsor is one of CS Wind’s most productive facilities and has the capability to build over 700 towers yearly. One of the most surprising things we learned is that the turbines themselves are not produced within the facility! Instead, the towers are manufactured here, while the turbines are shipped in from different manufacturing facilities and different companies.

The plant started operating in 2011 to provide towers for projects across North America and even the world. Ontario uses many of the towers locally as part of Ontario’s initiatives to increase renewable energy. We use the towers to create the large wind farms we all see around Chatham and Belle River. The plant is simply massive and encompasses many acres of land. CS Wind chose the site based on its proximity to highways (just in front of the plant), railways (which run at the back of the plant), and rivers. The plant has a very good operating record and celebrated two years with no safety infractions, despite currently producing hundreds of towers every year!

CS Wind Plant Tour

“Black Tower” Building

After Paolo finished his presentation, we went on a truly remarkable tour of the plant floor itself. It was simply incredible to be able to actually stand on a functioning factory floor. We were amidst all of the towers being assembled and could literally touch the huge components. The plant was closed when we visited so we were able to get a firsthand view of everything. Workers make the towers using specific steps: steel plates are cleaned, curved, and beveled, then joined together. Technicians then attach these large section piece by piece to make a tapered tower. All of this goes on in the gigantic “black tower” building. The towers leave this section of the plant with a black finish.

“White Tower” Building

The towers then move into the “white tower” building, which finishes the construction process. A huge oven bakes the towers to finish the construction. A technician then applies epoxy, followed by a urethane coating. While that may sound very complicated, Paolo explained that it is basically sunscreen. This allows the epoxy and paint last longer, which saves money and time. One of the critical parts of this coating process is maintaining a certain temperature. This ensures that the material sticks to the tower properly. The whole backing process has to restarted if the temperatures deviate too far from 140 degrees Celsius! Natural gas also powers all of the plant’s heating elements, which was very interesting. This links back to Union Gas, and how a relatively clean fossil fuel can facilitate our use of renewable energy!

Overall – CEI & CS Wind

In summary, our tour of the turbulence & energy lab, as well as CS Wind Canada, was remarkable. Researchers are developing great renewable technology like wind turbines and aerofoils at the CEI, including very interesting wind tunnel testing. Meanwhile, CS Wind Canada is using these technologies in real life at their manufacturing plant, helping Ontario transition to a more sustainable energy generation system. It was a completely novel experience to see both the research and practical aspects of these technologies!

Find out what else made the Deans List in Marcus’ daily CleanTech Academy recaps:

Find out what else made the Deans List in Marcus’ daily CleanTech Academy recaps:

DAY 1 DAY 2 DAY 3 DAY 4 DAY 5 DAY 6

Marcus Deans currently attends Académie Ste Cécile International School in Windsor and is looking forward to learning more about the technology and business world as part of WEtech Alliance. Outside of school, Marcus volunteers with the Canadian Cancer Society, the WindsorEssex Community Foundation, and the City of Windsor. He has also served in several leadership positions at youth-run companies as part of Junior Achievement. Marcus also enjoys science and has ranked internationally in youth science competitions as part of Team Canada.

He’ll be with us throughout the summer and will be reporting on his experience in our inaugural CleanTech Academy class through his CleanTech Blog posts.