Windsor, ON (April 6, 2020) – WEtech Alliance, a Windsor, Ontario-based Regional Innovation Centre (RIC), is teaming up with regional partners and Kelcom 3D to donate 500 face shields to essential workers across Windsor-Essex and Chatham-Kent.

“Technology has played a critical role in tracking, testing and treating COVID-19. As supply chains have been disrupted, 3D printing has helped with production continuity and rapid support” said Yvonne Pilon, President and CEO of WEtech Alliance.

Kelcom 3D is among dozens of companies and makers across Windsor-Essex and Chatham-Kent 3D printing face shields, masks, ventilator components and sanitizer dispensers to help front line workers combat COVID-19.

Kelcom 3D dropped off their first batch of protective face shields last week to Victoria Manor Supportive Housing, an organization offering residential supports and resource guidance services for those living with complex mental and physical health issues.

The team at Kelcom 3D has been working closely with industry partners and healthcare providers and workers to get rapid feedback on face shield design. The Kelcom 3D face shield, named the YQG Shield, has incorporated a unique bottom plastic retainer.

“The bottom retainer, narrower than the upper frame at the users forehead, will greatly improve protection” said Kevin Taylor, 3D Printer Consultant at Kelcom 3D. “This face mask is ideal for prevention of droplet spread to the health care workers (HCW) since the lower retainer prevents inhalation of respiratory droplets in the most susceptible zone. HCWs are always positioned standing above the patient who is on a stretcher — this makes the 1-2 feet below the HCW’s face the most susceptible area for spread of disease.”

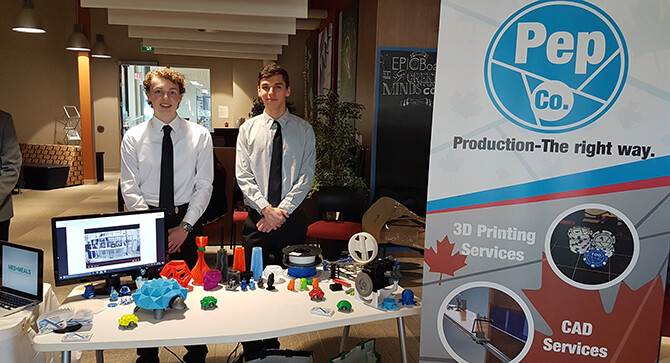

To assist with the production of face shields, Kelcom 3D will be working closely with Windsor based additive manufacturing startup, Pep Corp..

“When we heard of the PPE shortage it was important for Kelcom 3D to get involved early and do whatever we can you help fill shortage gap. Startups like Pep Corp. and entrepreneurs everywhere are scrambling to help during this crisis” said Leonard Colucci, Owner of Kelcom 3D Division. “We know that now more than ever, collaboration at all levels is key in the race to develop PPEs for our front line workers.”

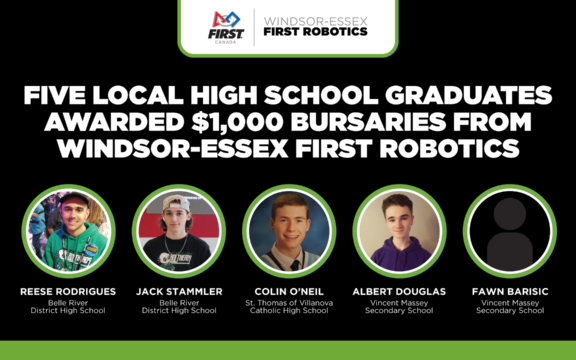

The University of Windsor’s EPICentre and Windsor-Essex FIRST Robotics are also lending a hand to help support the production of much needed face shields. Their organizations have announced financial support to Pep Corp. to assist with additional production.

“As one of our startups, we have been working with Pep Corp. for a long time.” said Wen Teoh, Director of EPICentre. “We are confident a little support will allow them to pivot their production process to help our community stay a little safer from the threat of COVID-19.”

“Parker joins a growing list of FIRST Robotics Alumni and Students across Canada who are helping 3D print PPEs for their respective communities” said Larry Koscielski, VP of Process and Technology Development at CenterLine and Chair of Windsor-Essex FIRST Robotics. “On behalf of Windsor-Essex FIRST Robotics, we are pleased to see our local Alumni continuing to practice the philosophies of FIRST.”

Right now Pep Corp. has the capacity to print about 250 face shields day.

Organizations in urgent need of donated face shields should email Michelle at info@wetech-alliance.com. To assist with distribution, quantities of 10 (minimum) to 50 (maximum) per organization will be offered along with pickup/delivery options.