Seven years after the company was launched to provide affordable, custom-made orthotics and sandals to customers with foot problems, a Windsor-based business has clients across the globe.

OLT Footcare uses state-of-the art 3D scanners and printers to craft midsoles and insoles to exact specifications, according to founder Yong Li.

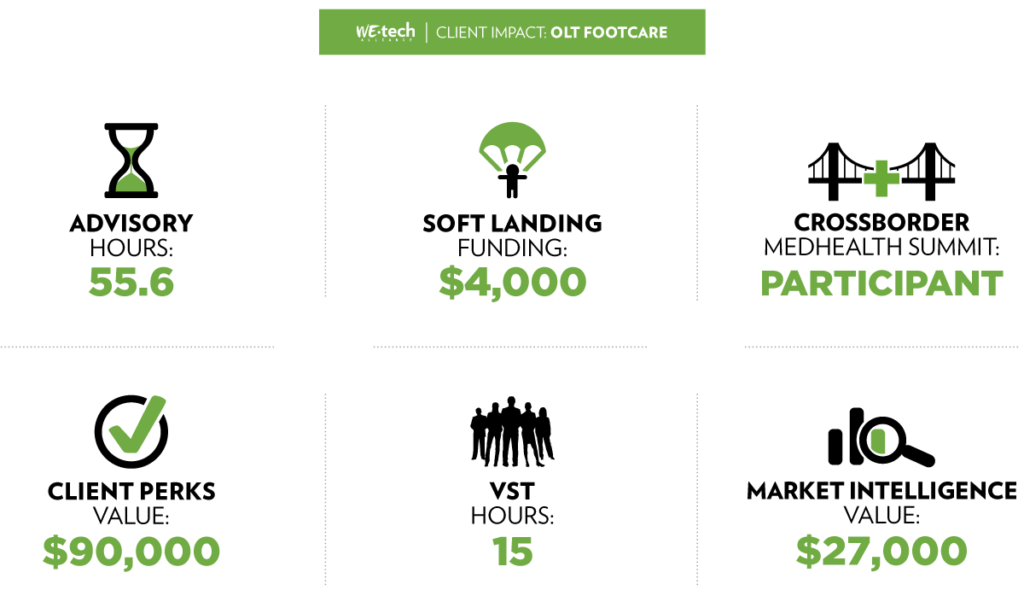

Li said the involvement of Adam Castle, WEtech’s director of venture services, and Deborah Livneh, was invaluable in the growth of his company.

“It has been a real pleasure coaching Yong. He is a true growth-oriented entrepreneur in his mindset. With his Ph.D. in Science, Dr. Li is constantly implementing the latest technology to improve and advance his businesses. I am impressed with the speed he has been able to expand his sophisticated product line and to acquire customers across the globe.” said Deborah Livneh, one of the Entrepreneur’s in Residence on the WEtech Alliance Venture Success Team, focused on scaling med-tech companies.

After launching his company in 2013, Li tapped into a suite of resources provided by the WEtech Alliance, including mentoring, tips on funding opportunities, legal advice and website development.

“WEtech’s soft-landing program also provided resources related to expansion and it allowed us to establish offices and foot-clinic partnerships in the United Kingdom, Australia, Malaysia, China and the U.S.” said Li.

Li also said his company’s involvement in WEtech’s Medhealth Summit supported expansion into the United States and allowed OLT to take a giant step forward. “Their advice and support has been invaluable.”

“OLT Footcare is a wonderful example of leveraging what we like to call “The Netflix” of business advisory services, “ says Castle. Delivering the right resources at the right time, has assisted OLT to move through each of our now well defined client streams, from Spark at the ideation level, to finding product-market fit and leveraging our advisor pool as a boost client, and now making use of our provincial and international network to compete in global markets.”

Li was working in the automotive industry in Michigan back in 2007 using 3D scanners and printers for quality control purposes when he took a phone call from an orthotics lab asking if 3D technology could be used in the foot-care industry.

“It was extremely expensive at the time but I realized there was a huge opportunity,” said Li. “As the costs came down, buying a scanner and a printer began to make more sense.”

Partnerships with foot-care clinics across the globe have kept the orders flowing into OLT’s plant on Windsor’s west-side where 3D scanners and printers produce custom-made products.

In preparation for producing the insoles as well as custom-made sandals, clients use a 3D scanner to take measurements of their patients’ feet or a foam box, provided by OLT, to produce an impression.

As Li explained, the scanners, roughly the size of a standard photocopier, can generate thousands of measurement points to exacting standards either by measuring a client’s foot or taking measurements from impressions or castings.

Once the impressions and measurements are generated, Li’s company uses its 3D printer technology to produce the footwear unless the clinic has access to its own 3D printer and can manufacture the footwear independently.

A desktop printer is used to produce a custom midsole. The sandals outer sole is then cut by a laser to match the midsole before the entire shoe goes through a final assembly process.

According to Li, the footwear will perfectly fit each foot to provide ultimate comfort and the correct amount of arch support.

OLT’s sandals are made up of a custom-measured 3D printed midsole, a laser-cut custom outsole and a pair of straps and buckles.

“We don’t work with standard shoe sizes because everyone’s foot is different and even a person’s left foot can have different measurements from the right,” said Li. “That’s why we use a 3D foot scanner so that the fit is perfect.”

Funding for development of the sandals was largely provided by a Kickstarter campaign which generated 400 orders in its first month when it was launched in 2017.

The company has also developed a dryer which removes moisture from 3D printed products and Li says OLT has sold more than 7,500 models to clients across the world.

“We have 20 distributors in Europe, Australia, Canada, the U.S. and Japan and our clients include NASA, Apple and Hewlett Packard,” said Li.

The company’s technology has resulted in visits from foot-care specialists from the United States and Australia.

The company currently has five employees at its Windsor manufacturing plant with plans to add more in the near future.